What is a Slit Coupling?

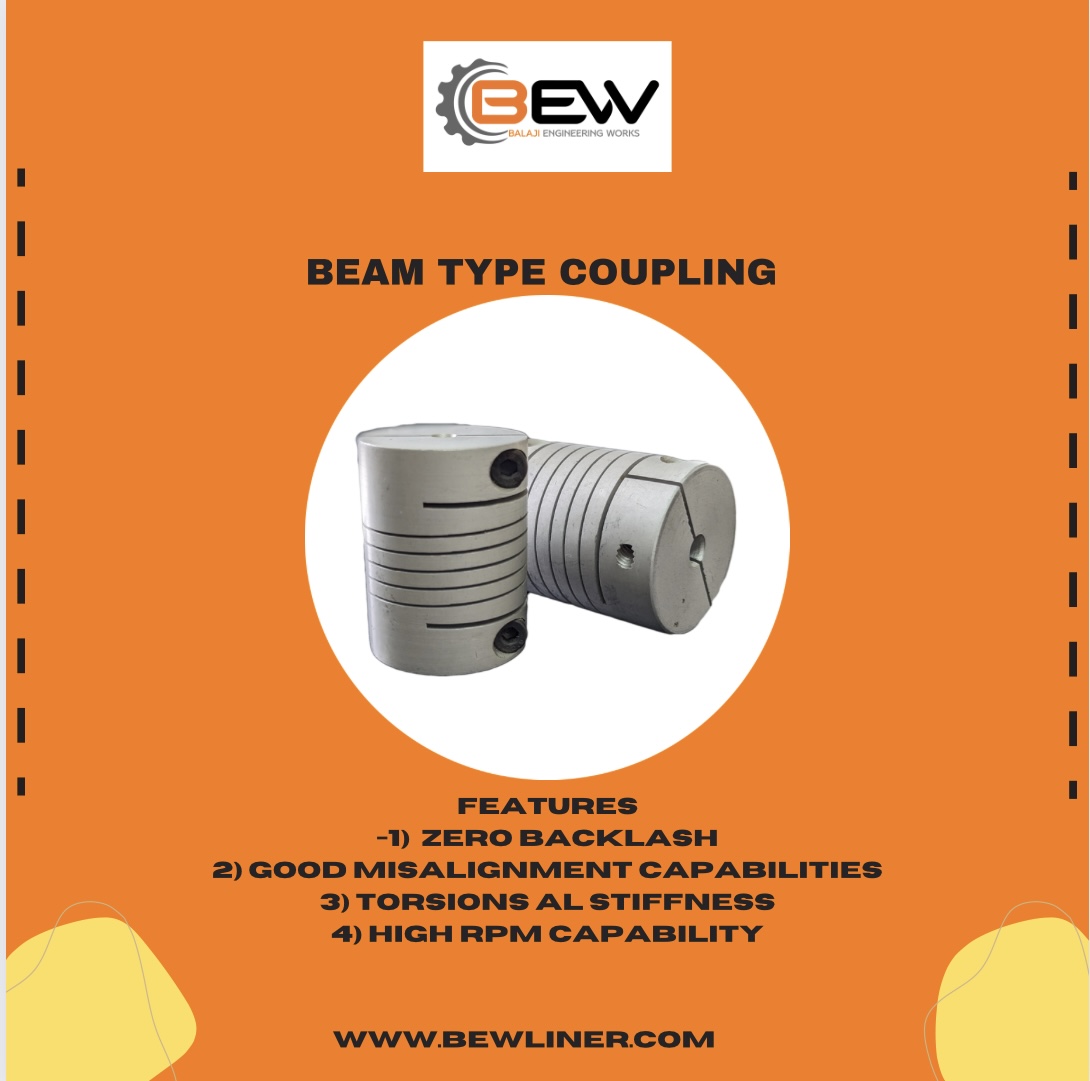

Beam couplings are a type of coupling that is used to connect two shafts together in order to transmit power and motion between them. The coupling consists of two hubs, one on each shaft, and a flexible beam that connects them. The beam can be made of various materials such as stainless steel, aluminum, or titanium, and it is designed to flex and absorb misalignments between the shafts. Beam Coupling compensates for the following types of misalignment: Axial and angular misalignment.

Benefits of Slit Couplings

One of the main advantages of beam couplings is their ability to handle misalignment between the two shafts. Misalignment can occur due to various reasons such as thermal expansion, vibration, or manufacturing tolerances. A beam coupling can compensate for this misalignment by flexing and allowing the two shafts to remain connected even if they are not perfectly aligned.

Another advantage of beam couplings is their compact size. Because the coupling relies on a flexible beam rather than a bulky mechanical mechanism, it can be used in applications where space is limited. In addition, beam couplings are lightweight and easy to install, making them a popular choice in a variety of industries.

How does a Beam Coupling work?

The beam coupling is installed on the two shafts, and the bolts are tightened to secure it. When the motor turns the first shaft, the torque is transmitted to the beam coupling. The beams in the coupling flex to accommodate any misalignment between the two shafts. The torque is then transmitted to the second shaft, which turns the load.

Applications of Beam Couplings

Beam couplings are also known for their high torsional stiffness, which means that they can transmit high torque loads without significant torsional deflection. This is important in applications where precise motion control is required, such as in robotics or machine tools.

There are different types of beam couplings available in the market, such as single-beam couplings, double-beam couplings, and helical beam couplings. Each type has its own advantages and disadvantages depending on the specific application requirements.

Key considerations when selecting an aluminum flexible coupling:

- Torque capacity: Ensure the coupling can handle the maximum torque of the application.

- Misalignment accommodation: Choose a coupling that can accommodate the expected misalignment.

- Speed rating: Select a coupling rated for the application’s operating speed.

- Bore size: Match the coupling’s bore size to the shaft sizes it will connect.

- Operating environment: Ensure the coupling’s material and finish suit the operating conditions.

- Cost: Balance budget considerations with the application’s requirements.

- Material of construction: Aluminum or stainless steel should be compatible with the operating environment and loads.

Contact Balaji Engineering Works or Consult a qualified engineer for assistance in selecting the appropriate coupling for your specific application.

Conclusion

In conclusion, beam couplings are a versatile and reliable way to connect two shafts. Their ability to compensate for misalignment, compact size, high torsional stiffness, and ease of installation make them a popular choice in a variety of industries. If you are looking for a coupling that can handle misalignment and transmit high torque loads, a beam coupling may be the right choice for your application.