Disc type couplings are a popular choice for power transmission applications in a variety of industries. They are known for their ability to accommodate shaft misalignment, high torque capacity, and long service life.

How Disc Couplings Work

Disc couplings transmit torque through a series of thin, flexible discs that are bolted between two hubs. The discs are typically made of stainless steel or a composite material, and they are designed to flex and bend to accommodate shaft misalignment.

Types of Disc Couplings

There are two main types of disc couplings: single-disc couplings and double-disc couplings.

- Single-disc couplings can accommodate angular and axial misalignment, but they cannot accommodate parallel misalignment.

- Double-disc couplings can accommodate all three types of misalignment: angular, axial, and parallel.

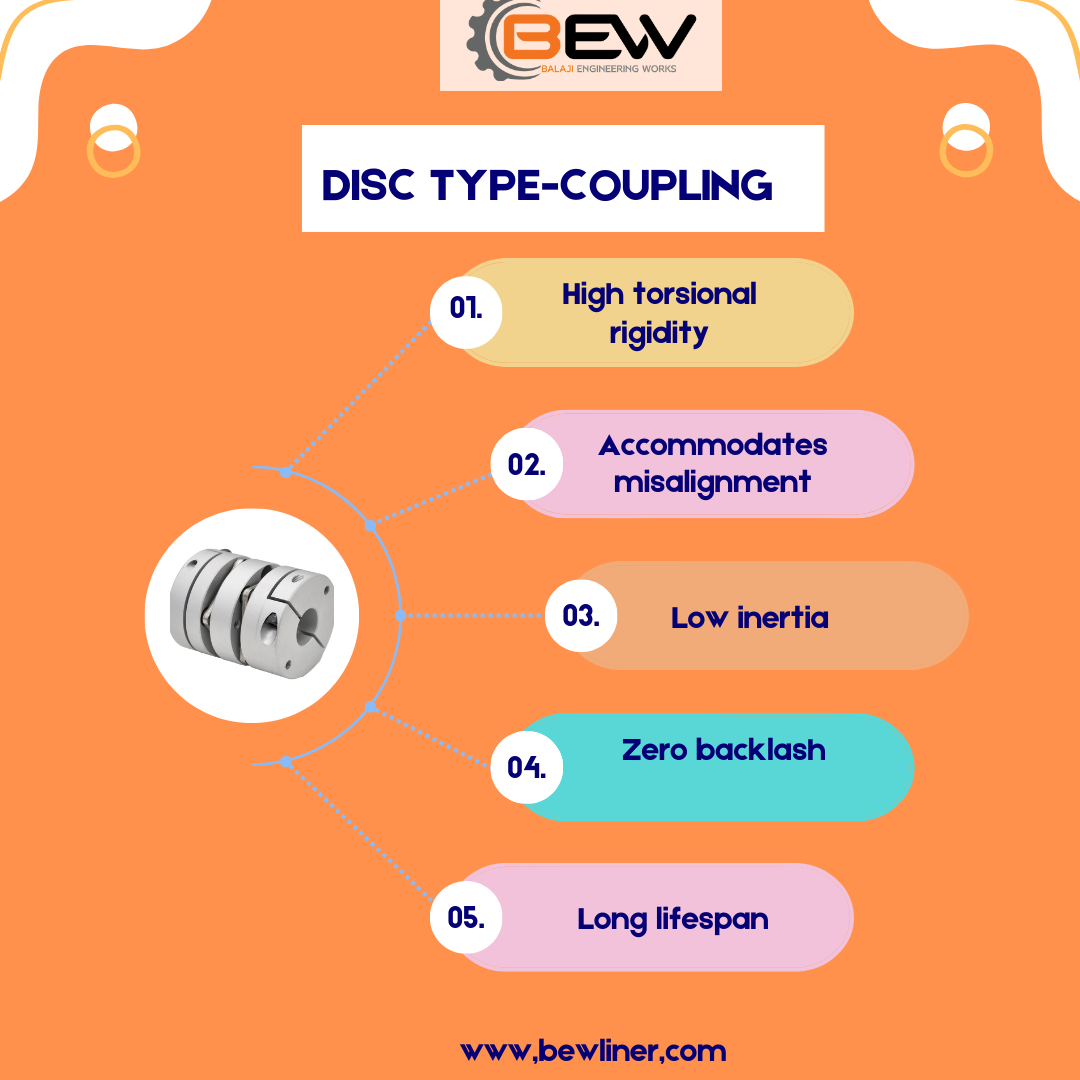

Advantages of Disc Couplings

Disc couplings offer a number of advantages over other types of couplings, including:

- High torque capacity: Disc couplings can handle high torque loads, making them ideal for heavy-duty applications.

- Low maintenance: Disc couplings are relatively maintenance-free, and they can operate for many years without requiring replacement.

- Long service life: Disc couplings have a long service life, making them a cost-effective choice for power transmission applications.

- Accommodates shaft misalignment: Disc couplings can accommodate all three types of shaft misalignment: angular, axial, and parallel. This makes them a good choice for applications where shaft misalignment is unavoidable.

Applications of Disc Couplings

Disc couplings are used in a wide variety of applications, including:

- Pumps

- Compressors

- Motors

- Generators

- Fans

- Blowers

- Mixers

- Agitators

- Conveyors

- Printing presses

- Paper machines

- Food processing equipment

- Textile machinery

- Mining equipment

How to Choose the Right Disc Coupling

When choosing a disc coupling, there are a number of factors to consider, including:

- Torque capacity: The coupling must be able to handle the maximum torque load of the application.

- Shaft misalignment: The coupling must be able to accommodate the amount of shaft misalignment that is expected in the application.

- Speed: The coupling must be able to operate at the speed of the application.

- Environment: The coupling must be made of materials that can withstand the environmental conditions of the application, such as temperature, humidity, and chemicals.

Conclusion

Disc couplings are a versatile and reliable type of coupling that can be used in a wide variety of applications. They are known for their high torque capacity, long service life, and ability to accommodate shaft misalignment. When choosing a disc coupling, it is important to consider the specific requirements of the application.